In part one of our series on R-22 phase out, we shared important factors you need to know about R-22 regulations, consumption allowances, and the importance of developing a strategy. In this post, we’ll focus on key risks associated with R-22, important considerations for building owners, managers, and facilities personnel, changes that could affect your new equipment selection, questions to ask your HVAC repair and management partner, and next steps.

Key Risks:

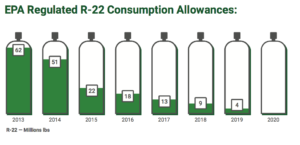

Since 2014, it has become increasingly more expensive to acquire R-22 refrigerant due to scarcity and inflated costs. Current prices can depend on a commercial HVAC representative’s negotiation with suppliers and quantity available/purchased. Depending on age and status of current HVAC equipment, here are a few key risks that building owners, managers and facilities personnel may face during the R-22 phase-out.

- Scarcity of R-22 refrigerant resulting in high maintenance costs when purchase is required

- Impending unavailability of R-22 refrigerant

- Business disruptions due to downtime of failed equipment not able to be repaired and/or re-charged

Important Considerations for Building Owners, Managers and Facilities Personnel:

There are many factors that should be considered when developing a strategy to implement the R-22 phase-out. Developing a strategy with the help of a knowledgeable HVAC facilities management partner will likely produce a more efficient, budget-conscious outcome that will put downtime and long-term savings at the forefront of your plan.

These are the important factors / questions that should be discussed with your HVAC repair and management partner:

- What impact will the transition plan make on business interruptions? For example, does the transition plan put you at risk of occupied space being without air conditioning for an extended period? Consider the time it will take to repair or obtain new air conditioning — leaving spaces temporarily unsuitable for occupancy, or unable to serve their critical functions.

- Have you considered a life-cycle assessment and determined the best choices for new equipment?

- Have you allowed enough time for professional engineering design and documentation to be discussed and implemented?

- Have you allowed sufficient time for the procurement process and equipment delivery lead time?

- Have you considered the cost of utilities and rebate incentives? When upgrading the new equipment is almost always more efficient.

Engineering a Streamlined & Efficient System Upgrade:

Retrofitting or “renewing” systems with alternatives to R-22 may be a viable option for some properties. However, there are several reasons why these solutions may not be the best decision. The reasons can vary from the cost or unavailability of alternative refrigerants, cost of energy, to deferred repairs that may cause you to look at replacing the equipment instead of retrofitting.

Changes that could greatly affect your selection of new equipment include:

- Use of data-driven technology to assess heat load and aid lifecycle planning and energy management

- Building design changes or modifications such as window lm, improved roof insulation as a result of a reroof, and most importantly lighting upgrades (LED retro t perhaps?) may result in a reduced heat load – permitting the installation of lower capacity systems

- Construction modifications that would require capacity upgrade to ensure a comfortable indoor environment – e.g. rooms added, areas demolished, layout altered, space function alterations, walls added or removed, etc.

- Occupancy volume changes – more or less people in the same space means different loads on HVAC units

- Technological changes in the types of equipment available – some system configurations may change due to advances in equipment design and capabilities

- Changes to building code (think title 24 in California for example)

Next Steps:

- Take Action: The R-22 phase-out process does not need to be a painful one. Consider your options and start discussions with HVAC experts who can help you make the best decisions for your facilities. Get started now to put a plan into place that complies with EPA regulations.

- Understand Refrigerant Options: Your choice of refrigerant will likely affect your system’s capacity, temperature glide, and operating pressures, etc. Work with your HVAC management partner to research options, manufacturers, and more.

- Allow Enough Time: You don’t want to feel pressured to make a decision because you did not allow for enough time. Understand the time it takes to transition or upgrade a system. Plan for the time it will take for scheduling, conversions and putting the necessary resources into place.

With the R-22 phase-out well underway and the impending extinction date in the near future, it is essential that building owners, managers and facilities personnel take action by working alongside a knowledgeable HVAC repair, maintenance, and management professional to ensure a seamless transition.

To learn more about the R-22 phase out and explore options to improve your HVAC efficiencies, contact the experts at Evergreen Air Conditioning.

Download the full guide to R-22 Phase Out for Facilities Management here.